- 168#,Yuelu Avenue Steel Industrial Zone, Changsha, China

- 0086-731-88787784

- sales@permanentsteelpipe.com

Marking Workflow

1.Ensure all tests are performed on piping system before starting painting work.

2.Clean painting surface to remove oils, grease, dirt.

3.Ensure proper room temperature and humidity levels.

4.Use hand tools, machine tools, shot blasters etc to clean surface as per relevant standards and project requirements.

5.Apply primer within 4 hours of surface preparation.

6.Apply paint coats after previous coats have dried up, as per instructions of paint manufacturer.

Note:Stainless steel piping is not painted. Identification marking may be done on this piping.

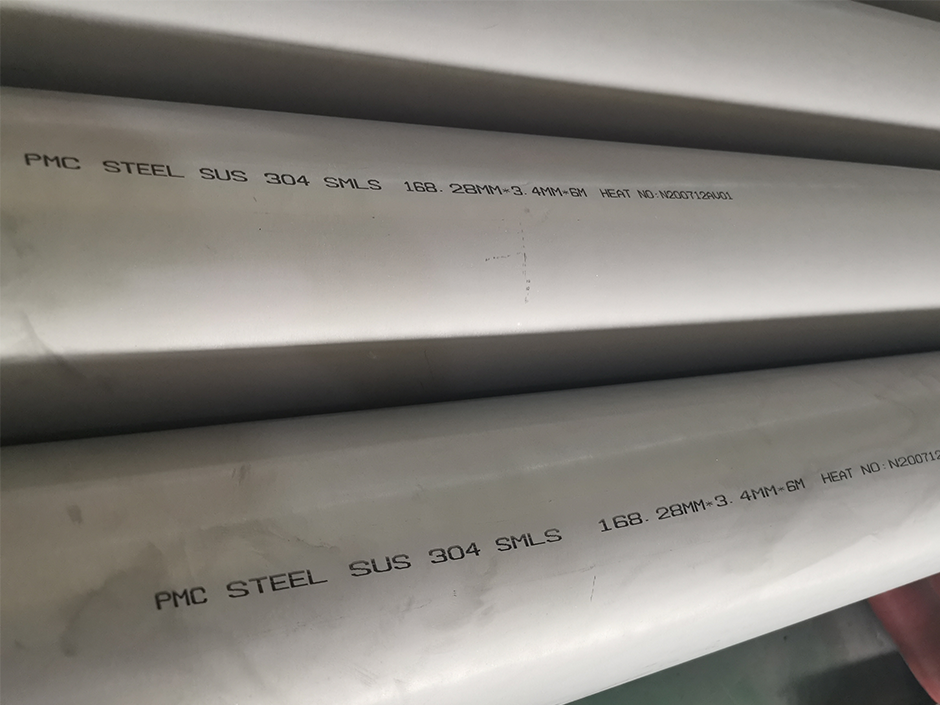

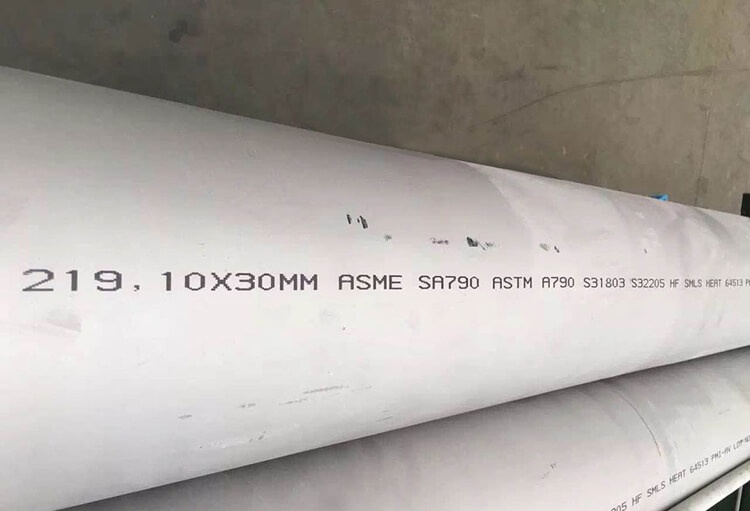

Marking on steel pipe

1.Manufacturer name or his registered trademark;

2.Standard of steel products;

3.The grade of the material;

4.The heat number;

5.Pipe number;

6.Wall thickness;

7.Actual length;

8.Out diameter;