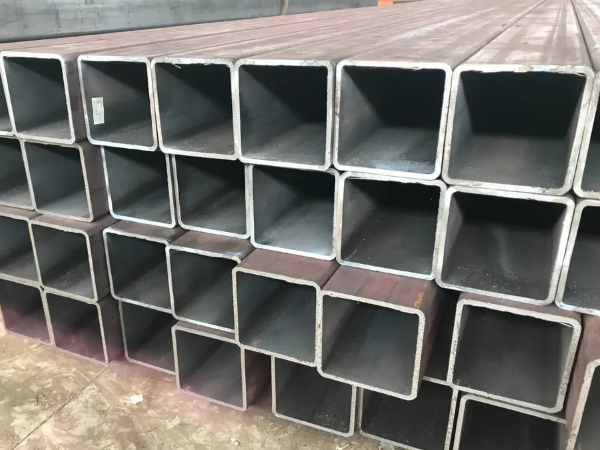

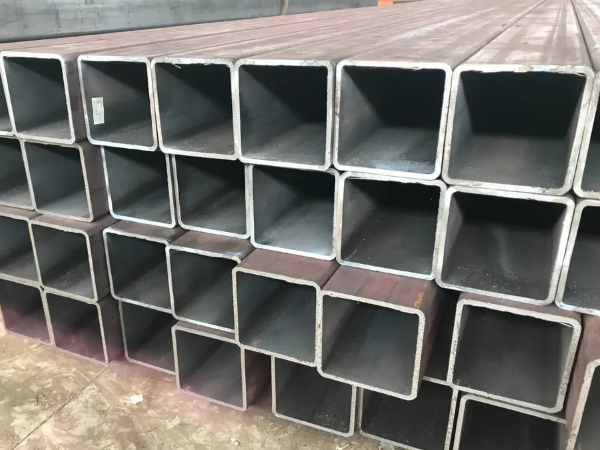

Matters Needing Attention When Phosphating Q345B Square Tube

Date:2022-04-11View:1280Tags:Square Tube

Phosphating is a whole process of organic chemical and electrochemical corrosion to generate polyphosphate conversion film. The established polyphosphate conversion film is collectively referred to as phosphating film. It can play a very large effect and can improve the anti-corrosion ability of the q345b square tube. When we carry out phosphating treatment of q345b square tube, we should pay special attention to the following points:

1. Overflow water cleaning

Washing with overflow water to ensure that the q345b square tube is sufficiently flushed and tidy to reduce the condition of stringing grooves. When overflowing, it needs to seep water from the bottom end, and open a water hole above the diagonal for overflow.

2. Phosphating slag discharge

The phosphating solution will produce more or less residue, and it should be indicated that it is equipped with phosphating slag discharge equipment when the technology is formulated. Especially for the self-spraying phosphating of q345b square tube, the slag discharge equipment is indispensable. The typical slag discharge equipment includes: inclined column accumulator, upper deposition tower, centrifugal slag discharger, paper cloth bag precipitation, etc.

3. Time interval

If the time interval between each step is too long, it will cause secondary corrosion of the q345b square tube during operation. Especially in pickling, after pickling and passivation, the pipe fittings are easy to oxidize and rust in the air and turn green. It should be equipped with shrink water maintenance between processes to reduce rust; however, the time interval is short, and it is not possible to control the dry water sufficiently and reasonably. parts, resulting in the condition of the string tank, and even the tank liquid is damaged. Therefore, when considering the time interval of the process flow of the q345b square tube, an appropriate time interval should be selected according to the specific situation.

4. Pickling tank heating pipe

As far as possible, the selection of the material of the heating pipe of the pickling tank is not the content of the structural design. If no prompt is given, it is likely to lead to the carelessness of the staff when designing the mechanical equipment. For acid pickling and passivation with hydrochloric acid and sulfuric acid, the materials for the pickling tank are only glass fiber reinforced plastics, granite, and plastic. The heating pipes can only use lead-antimony alloy pipes and ceramic pipes, and stainless steel plates cannot be used. If ammonium sulfate is selected for pickling and passivation, the raw materials of the pickling tank and heating pipe can be made of stainless steel plate, natural glass fiber reinforced plastic, plastic, granite, etc.

5. Processing hole

For the q345b square pipe that is prone to water storage in the blind area, a suitable place should be selected to drill the processing holes to ensure that the water can be fully drained in a short period of time. Otherwise, it will lead to stringing of grooves or long-term drying at high altitude, resulting in secondary corrosion and affecting the actual effect of phosphating.