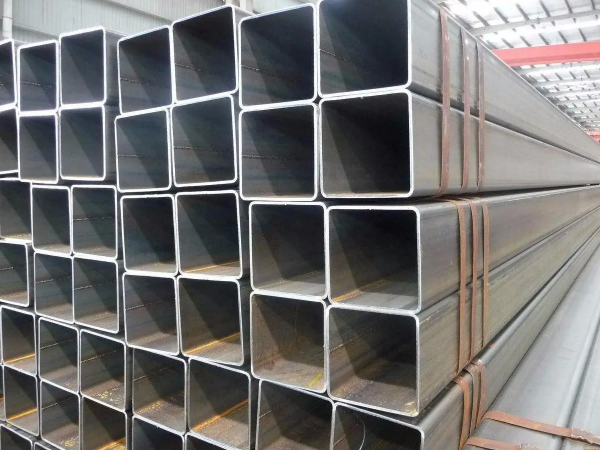

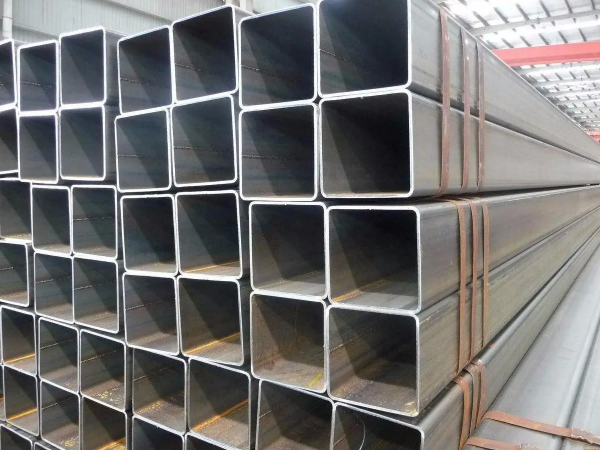

Performance Index Analysis of Square Tube

Date:2022-03-30View:1313Tags:Square Tube,Performance Index

Square tube is a name for a square tube, that is, a steel tube with equal side lengths; it is a strip of steel that has been processed and rolled. The square tube is divided into seamless and welded, and the seamless square tube is formed by extruding a seamless round tube. Generally used in construction, machinery manufacturing, steel construction and other projects, shipbuilding, solar power brackets, power engineering, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, boiler construction, highway railings, housing construction, pressure vessels, oil storage Tanks, bridges, power station equipment, lifting and transportation machinery and other welded structural parts with higher loads, etc.

Performance index analysis of square tube:

1) Plasticity

Plasticity refers to the ability of metal materials to produce plastic deformation (permanent deformation) without damage under load;

2) Hardness

Hardness is a measure of the softness and hardness of metal materials. At present, the most commonly used method for measuring hardness in production is the indentation hardness method, which uses an indenter with a certain geometric shape to press into the surface of the tested metal material under a certain load, and determines its hardness value according to the degree of indentation;

Commonly used methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV) methods;

3) Fatigue

The strength, plasticity, and hardness discussed above are all indicators of the mechanical properties of metals under static load. In fact, many machine parts work under cyclic loads, under which conditions the parts will fatigue;

4) Impact toughness

The load acting on the machine at a high speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness;

5) Strength

Strength refers to the resistance of a metal material to failure (excessive plastic deformation or fracture) under static load. Since the action of the load is in the form of tension, compression, bending, shearing, etc., the strength is also divided into tensile strength, compressive strength, bending strength, shear strength, etc. There is often a certain relationship between various strengths, and tensile strength is generally used as the most basic strength indicator.