Precautions When Installing Rectangular Tubes

Date:2022-04-01View:1299Tags:Rectangular Tubes

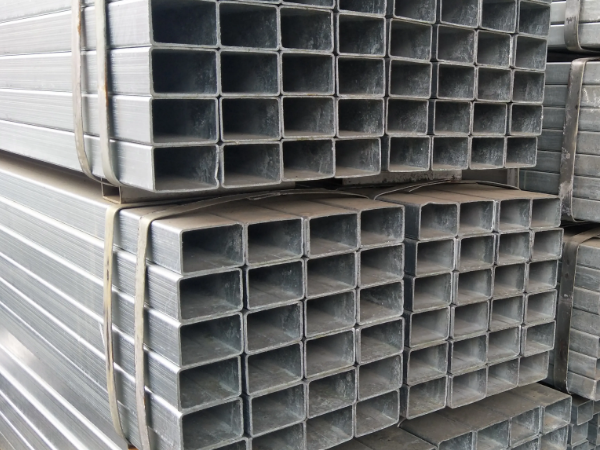

Rectangular tube is one of the common pipe fittings in daily life, and is widely used in engineering construction, roads, highways and bridges, power plants and other fields. Because of its loadability, reflection, etc., it is loved by everyone. In order to better increase the use time of the rectangular tube and reduce the cost, we have done maintenance in the whole process of assembly, so what should be paid attention to when installing the rectangular tube?

1) When the rectangular tube is installed, it should not be in direct contact with concrete, cement mortar and concrete, and the surface should be covered with anti-corrosion tape;

2) When the rectangular tube is buried in the ground, damage to the pipe due to sharp lumps or oxidant corrosion on the surface of the pipe should be avoided. In addition, other anti-corrosion solutions for medical supplies can also be applied, such as double-layer epoxy resin adhesive epoxy primer or epoxy glue, anti-corrosion glass fiber reinforced plastic film, double-layer polyethylene tape or double-layer styrene tape, etc.;

3) When the rectangular tube is used to add cement mortar, the raw material of insulating casing should be used to ensure that there is a certain gap between the cement mortar and the pipeline, so that the pipeline can expand and contract at will;

4) During the installation process, the axis lines of the fixed tube and the movable tube should be in a straight line, otherwise the rectangular tube will easily push the rubber ring out, which will affect the quality and speed of the installation. The rectangular tube should be installed flat, and the rectangular tubes should be in a straight line. Be careful when there is an inclined angle; align the interface connecting the rectangular tube with the socket. If the insertion resistance is too large, do not force it to prevent the rubber ring. Twisted; vegetable oil should be used for the lubricating oil of the rubber ring. In cold winter, the rubber ring can be preheated with hot water to reduce the hardness and install it quickly;

5) When the rectangular tube is connected with the fittings such as the nozzle, tap, wireless remote water meter, etc., the rectangular tube cannot have inch threads, and should be connected with the transfer type connector;

6) Equipping rectangular tubes and industrial equipment with insulating sleeves, cooling water treatment equipment and heating equipment;

7) Clean and apply the rubber ring. Clean the adhesive on the rubber ring, bend the rubber ring into a "plum shape" or a figure 8 shape and put it into the socket groove, and press it along the entire rubber ring with your hand, or use a rubber hammer to smash it firmly to ensure that the The part is not warped or twisted, and is evenly stuck in the groove;

8) After assembling and testing the pipeline, water with low chloride ion content and 0.03 solution should be used to remove surface contaminants.