The Performance Characteristics of Thick-walled Square Tube

Date:2022-02-24View:1388Tags:Square Tube

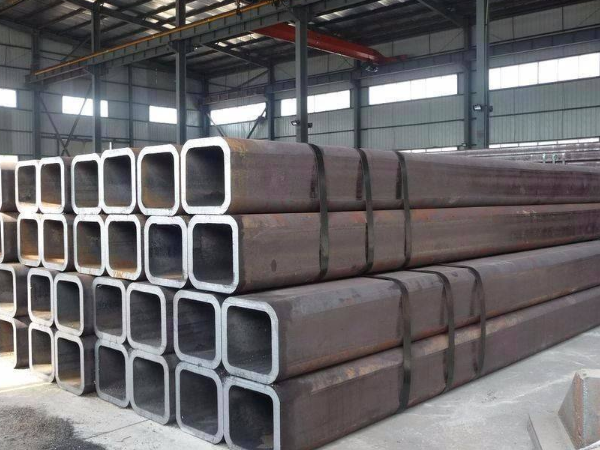

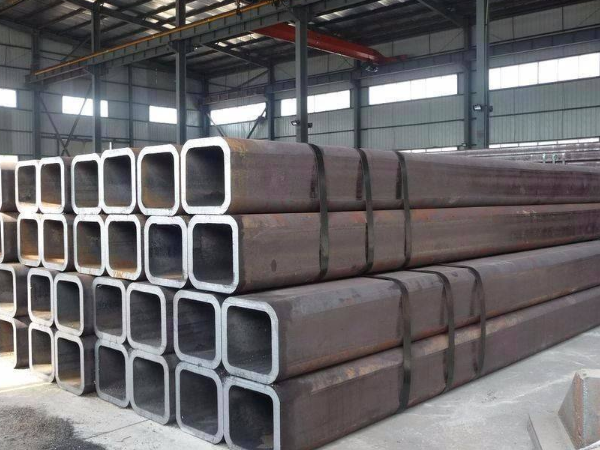

Thick-walled square tube is a kind of hollow square-section light-weight thick-walled steel pipe, also known as steel refrigeration bending profile. It is made of Q235 hot-rolled or cold-rolled strip or coil as the base material, which is formed by cold bending and then high-frequency welding. In addition to the thickening of the wall thickness of the hot-rolled extra-thick-walled square tube, its corner size and edge straightness have reached or even exceeded the level of the resistance-welded cold-formed square tube.

What are the characteristics of the thick-walled square tube?

1) Large size

The maximum specification of the square tube production line used in the process is 500mm*500mm*19mm, ranking second in the world. The world's No. 1 Nippon Steel 26-inch square and rectangular tube production line has a maximum specification of 550mm*550mm*22mm. At present, the largest square and rectangular tube in European and American countries is 400*400*12.7mm.

In recent years, with the country's investment in capital construction, more and more major municipal projects and construction projects in various places have adopted the form of steel structures, while large-scale thick-walled square tubes are beautiful in appearance, reasonable in force, and relatively simple in node handling. Therefore, it is widely used as a steel member in the truss structure system and curtain wall support system of airport terminals, stadiums and exhibition centers, etc. But in practical application, the square tube also encountered some problems that need to be solved urgently.

2) High strength

In order to reduce self-weight and improve safety performance such as earthquake resistance and impact resistance, high-strength steel has been widely used at home and abroad, and the material strength limit has reached 630MPa or even higher. The tensile strength of the base metal of the square tubes produced by the process can reach 630Mpa, ranking first in the world according to the product strength grade.

3) The product is super thick

The maximum thickness of the square tubes produced by the process is 19mm, and the super-thickness is not only reflected in the absolute thickness, but also in the relative thickness of the product. The thickness is an important indicator of the difficulty of cold forming, and the square tube is expressed by the side thickness ratio. At present, it is generally believed at home and abroad that when the edge-to-thickness ratio is lower than 10, the product has high forming difficulty. The square tubes produced by the process have a small section and large wall thickness products with a side thickness ratio of up to 7, such as 100mm*100mm*14mm, 120mm*120mm*16mm, etc.

4) Refractory

The cold-formed large-sized thick-walled square tube made of B490RNQ hot-coiled steel, its room temperature mechanical properties fully meet and exceed the requirements of the national standard Q345B, its forming performance is equal to or better than that of Q345B, and its yield-strength ratio meets the requirements of the national construction industry standard on seismic resistance. requirements. At the same time, its high temperature performance is significantly better than that of Q345B of the same level. At 600, the yield strength of B490RNQ remains at 310MPa, which is much higher than 2/3 of the room temperature yield strength, while the yield strength of Q345B in the 500 process has a wall thickness of more than 8mm, which is lower than 2 /3 Room temperature yield strength.