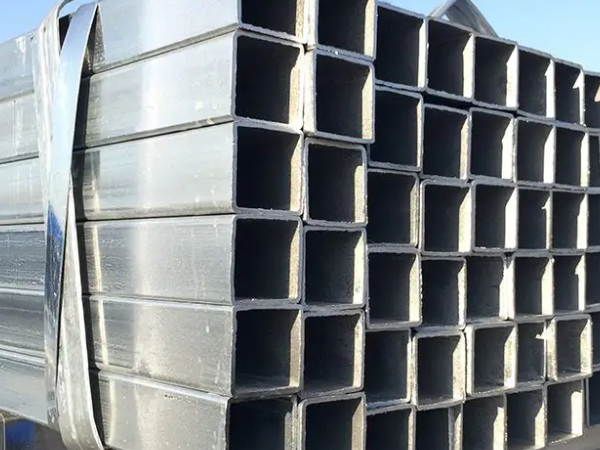

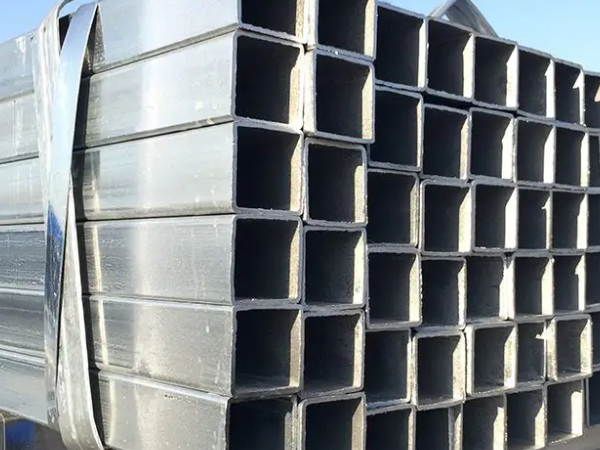

Cold Drawing Process of Q235B Rectangular Tube

Date:2022-03-18View:1313Tags:Rectangular Tube,Cold Drawing Process

Process flow of q235b rectangular tube:

Tube blank → heating → perforation → heading → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → billet tube → heat treatment → straightening → hydraulic test (flaw detection) → marking → storage .

Why does q235b need to be cold drawn?

1) The q235b rectangular tube that has been cold-drawn has the characteristics of excellent surface finish. This smooth appearance can make the product achieve a larger score in terms of aesthetics, thus winning the favor of many consumers;

2) Due to the variety of product specifications, the thickness of the cold-drawn pipe can be between 8-50MM and the width can be guaranteed to be between 150-625MM, which can meet the needs of customers, and can even be used instead of medium plate profiles, avoiding re-cutting. The user can directly carry out the welding operation;

3) The size of the pipe is kept accurate, the appearance is straight, the sides are more vertical, the water chestnut is also very obvious, good shape and excellent texture;

4) The rigidity of steel will be relatively hard, and it has the characteristics of good surface flatness.

The reason why the q235b rectangular pipe is cold drawn is to better promote the hardness of the product, so as to better ensure the quality of the pipe, so that users can use it better. Because the cost of cold drawing is slightly higher, the price of the pipe will also be higher rose slightly.

What should be paid attention to before cold drawing of q235b rectangular tube?

1) The pickling and rust removal should be thorough. Once the unremoved rust is found, it needs to be pickled again;

2) During production, the component concentration of phosphating solution and saponification solution should be tested frequently to ensure the production index of phosphating solution and saponification solution.

3) The temperature and operation time of the treatment liquid should be strictly controlled.