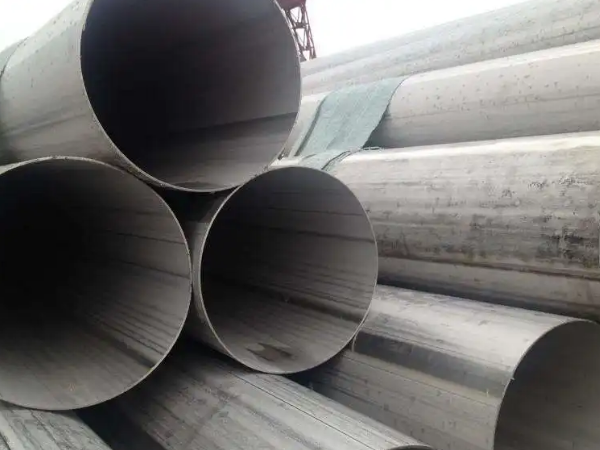

Methods to Improve the Surface Quality of Stainless Steel Welded Pipe

Date:2022-05-19View:1948Tags:Stainless Steel Welded Pipe, Surface Quality

Stainless steel welded pipe is a steel pipe made of steel or steel strip that is welded after being curled and formed by a set and mold, which has the advantages of simple production process, high production efficiency, many varieties and specifications, and low investment in equipment.

In the production process of stainless steel welded pipe, improve its surface quality can effectively extend its service life. Improving the surface quality of stainless steel welded pipe includes improving the surface morphology and structure, reducing the number of interlayer, etc. So how to improve the surface quality of stainless steel welded pipe?

At present, the common surface treatment methods on the market are mechanical drawing, mechanical grinding, polishing and coloring treatment, etc.

1、Mechanical drawing

Mechanical drawing is to increase the surface roughness of the pipe by plug precision cold drawing, which can improve the surface structure of the pipe, but will not improve the morphological structure of the stainless steel welded pipe, the energy level and the number of interlayer. This is a basic surface treatment process, while the roughness created by the process is also the basis for other more complex surface treatment processes.

This treatment is often used to improve the surface brightness of stainless steel welded pipe, but although the Ra value may be good, many cracks can be seen under the electron microscope, the actual surface area is expanded, and there will be locally separated ferrite and martensite tissue. The surface of stainless steel welded pipe is entrapped with many impurities, such as abrasive particles. In addition because of the use of polishing paste, so a lot of energy will be stored in the resulting depressions, resulting in the number of media also increased.

2、Polishing

Commonly used polishing are mechanical polishing, chemical polishing, electrochemical polishing, etc.. With the help of abrasives in the polishing agent on the surface of the parts of the polishing effect, so that the surface of the stainless steel welded pipe smooth, to polishing effect. Polishing can be obtained after the surface roughness of 0.4um below the mirror bright.

Mechanical polishing of stainless steel welded pipe surface grinding is very small, it is difficult to polish the rough surface. This requires pre-polishing, grinding wheel, grinding belt with polishing paste for grinding, divided into coarse grinding, medium grinding and fine grinding. Surface roughness after fine grinding can reach 0.4um. In order to achieve some other requirements, such as de-oxidation, deburring, de-welding slag, matting and other purposes, sometimes also sandblasting, shot blasting and brush light with steel wire wheel surface treatment, polished surface with stainless steel wire wheel can better avoid iron pollution.

Chemical polishing is the stainless steel welded pipe immersed in the appropriate solution, because the solution on the surface of the convex parts than the concave parts dissolved faster, so that the surface flattening, to achieve polishing purposes. Generally speaking, the polishing ability of chemical polishing is poor, only a small amount to improve the brightness. But the mechanical polishing than the labor-saving, time-saving, and can be polished on the inner surface of small parts.

3、Surface coloring treatment

Stainless steel welded pipe surface coloring not only gives stainless steel welded pipe a variety of colors, increasing the variety of products, but also to improve product wear resistance and corrosion resistance.